Key Factors Influencing Adult Diaper Absorbency

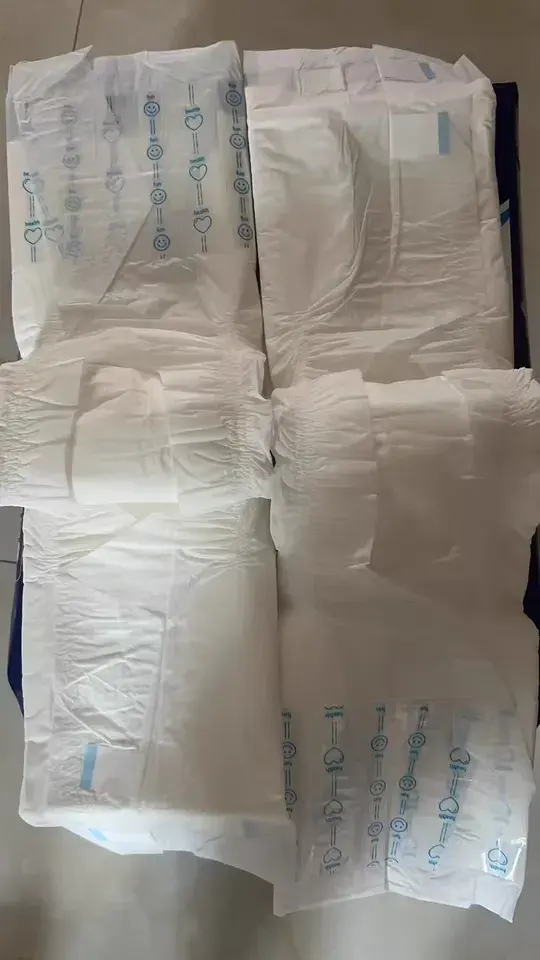

If you’re looking for a highly absorbent solution that prevents leaks all night long, check out our heavy duty overnight adult diapers.

- SAP (Super Absorbent Polymer) drives absorbency and anti-rewet under pressure; its crosslinking, particle size, and surface treatment determine speed, capacity, and gel permeability.

- Electrolytes matter: absorption in 0.9% NaCl is typically about one-tenth of that in deionized water, so saline performance—not DI water—is what counts.

- Fluff pulp still does five things: (1) scaffolds the core and fixes SAP, (2) spreads liquid by capillarity, (3) temporarily stores surges (2nd/3rd wet), (4) mitigates gel blocking, (5) adds limited absorption but does not lock liquid under load.

- For ultra-thin diapers (reduced fluff): increase SAP quality and amount, and tune structure/process to preserve fast acquisition, multi-insult performance, and low rewet.

- Design priority: fast first/repeat acquisition (≤10–30 s), high AUL, good gel bed permeability, and low rewet—not just extreme free-swelling ratios.

1) What Is SAP and Why It Matters

Super Absorbent Polymer (SAP) is a functional polymer that absorbs hundreds to thousands of times its own weight in water and retains it as a hydrogel, even under pressure. It is widely used in personal hygiene, agriculture, construction, packaging, cosmetics, and medical applications.

2) Chemistry and Main Families

SAPs are macromolecular electrolytes containing hydrophilic groups and a crosslinked network. Early materials were starch-graft polyacrylonitrile (Fanta et al.). Families include:

- Starch-based (grafted, carboxymethylated, etc.)

- Cellulose-based (carboxymethylated, grafts)

- Synthetic polymers: chiefly polyacrylic acid salts, plus poly(vinyl alcohol), poly(ethylene oxide), etc.

Today, polyacrylate SAPs dominate (~80%) for cost, process simplicity, high capacity, and shelf stability.

3) How SAP Absorbs and Retains Liquid

- Before wetting, chains are coiled and crosslinked into a network.

- Upon wetting, capillarity and diffusion bring water into the resin.

- Ionizable groups dissociate; electrostatic repulsion expands the chains.

- Counter-ions remain inside, creating an osmotic pressure difference that drives further water influx.

- Crosslinks and hydrogen bonding limit unlimited swelling, stabilizing the hydrogel.

4) Electrolyte (Salt) Effect

Salts reduce the osmotic driving force and shield charges, shrinking the polymer network. As a result, SAP absorbency in 0.9% NaCl is typically ~1/10 of that in deionized water—critical for real urine conditions.

5) Thermodynamics of “Locking” Water

Absorption is spontaneous (free energy decreases) until equilibrium. Differential thermal analysis shows that even at 150 °C, about 50% of water remains trapped in the gel network. At room temperature, pressure alone cannot easily expel this water—explaining SAP’s strong anti-rewet behavior.

6) A Brief History

- 1961: USDA NRRC develops starch-graft acrylonitrile (HSPAN), surpassing traditional absorbents.

- 1978: Sanyo Chemical (Japan) first uses SAP in disposable diapers.

- Late 1970s: UCC (USA) makes non-ionic SAPs via radiation crosslinking (absorbency up to 2000×).

- 1983: Sanyo synthesizes high-absorbency polymers from potassium acrylate with diacrylamide crosslinkers; then iterates modified polyacrylates/polyacrylamides.

- By the late 20th century: Nippon Shokubai, Sanyo, and Stockhausen hold ~70% market share through cooperation.

7) Where SAP Is Used

- Hygiene (~70%): diapers and pads.

- Agriculture/forestry: soil moisture retention, improved germination/drought tolerance, better aeration.

- Packaging: anti-fog/anti-condensation films to keep foods fresh.

- Cosmetics: rheology modifier/thickener.

- Industry: water-selective dewatering agents.

- Medical: absorbent dressings, artificial skins permeable to water/drugs but not microbes—leveraging SAP’s biocompatibility.

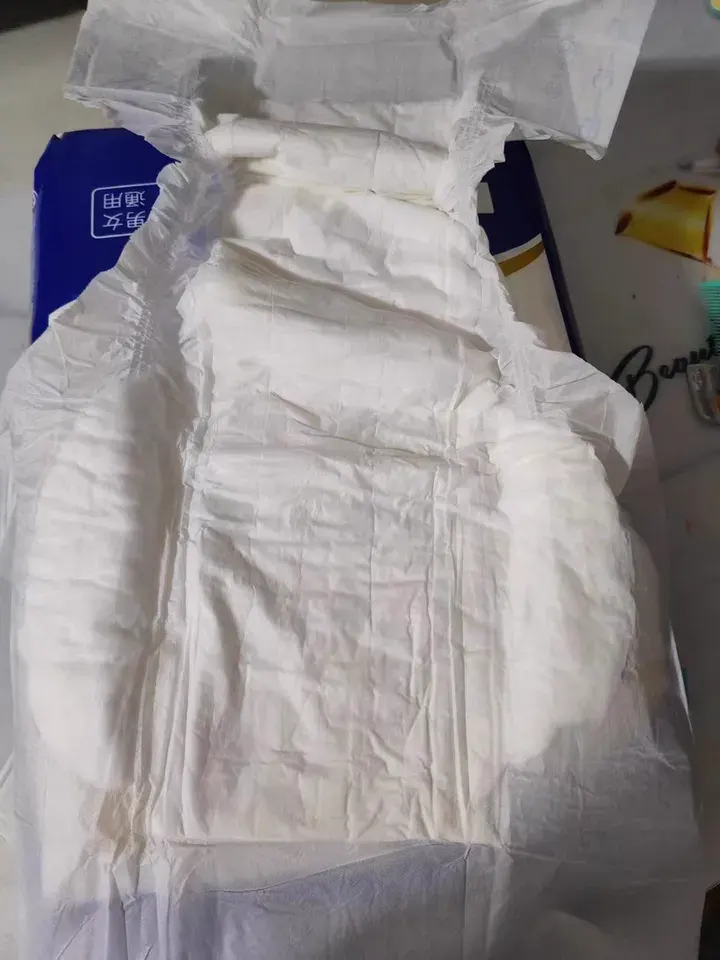

8) Why Ultra-Thin Diapers Are Thin—and the Trade-offs

Ultra-thin diapers reduce fluff pulp to improve comfort and slimness. To maintain total capacity, acquisition speed, and multi-insult performance with less fluff, SAP selection/level and process parameters must be adjusted.

9) The Five Functions of Fluff Pulp (Even When Minimized)

- Core scaffold: builds the pad, fixes SAP, prevents deformation.

- Capillary spreading: rapidly distributes urine, increasing SAP utilization.

- Temporary storage: buffers surges (especially 2nd/3rd wet) to prevent side/back leakage.

- Gel-block mitigation: fiber matrix maintains liquid pathways, aiding repeat absorption.

- Some absorption (~10–15×), but no true liquid locking—under pressure, liquid can re-emerge.

Design implication: Reducing fluff requires compensating via SAP quality, distribution, and core architecture.

10) Simple Comparative Experiments (to Guide SAP Choice)

A. First-insult speed test

Weigh 2 g SAP vs 2 g milled fluff in 100 mL beakers; add 10 mL, 37 °C synthetic urine. Fluff absorbs faster.

→ Prioritize fast-acquisition SAP.

B. Second-insult speed test

Add another 10 mL under the same conditions; fluff still faster (within its capacity limit).

→ Prioritize fast multi-insult absorption.

C. V-groove diffusion test

Place 2 g SAP vs 2 g milled fluff in V-grooves; drip 10 mL at one end. Fluff spreads farther; SAP shows gel blocking. Different SAPs vary in diffusion distance.

→ Prioritize good permeability/through-flow SAP—or compensate via process/structure.

11) Practical Design Guidance for Ultra-Thin Cores

- When fluff is reduced, increase SAP level and ensure good multi-insult performance.

- Beware structural instability and gel blocking at high SAP loadings; smart core design (zoning, channels, embossing, density control) can avoid these pitfalls.

- In practice, urine not absorbed within ~10 s risks leakage; with a small amount of retained fluff/fiber, the window can relax to ≤30 s because fluff temporarily holds liquid while SAP finishes absorption.

12) Bottom Line

For adult diapers—where saline conditions, body pressure, and repeated wettings are the norm—fast acquisition, high absorbency under load, strong gel permeability, and low rewet are the performance pillars. Achieve them by pairing the right SAP (chemistry, crosslinking, particle size, surface treatment) with enough fluff structure and an optimized core architecture to counter gel blocking and stabilize multi-insult absorbency.

For long, leak-free sleep, choose heavy-duty overnight adult diapers with maximum absorbency and 3D leak guards. If you need OEM/ODM specs, request a quote here.