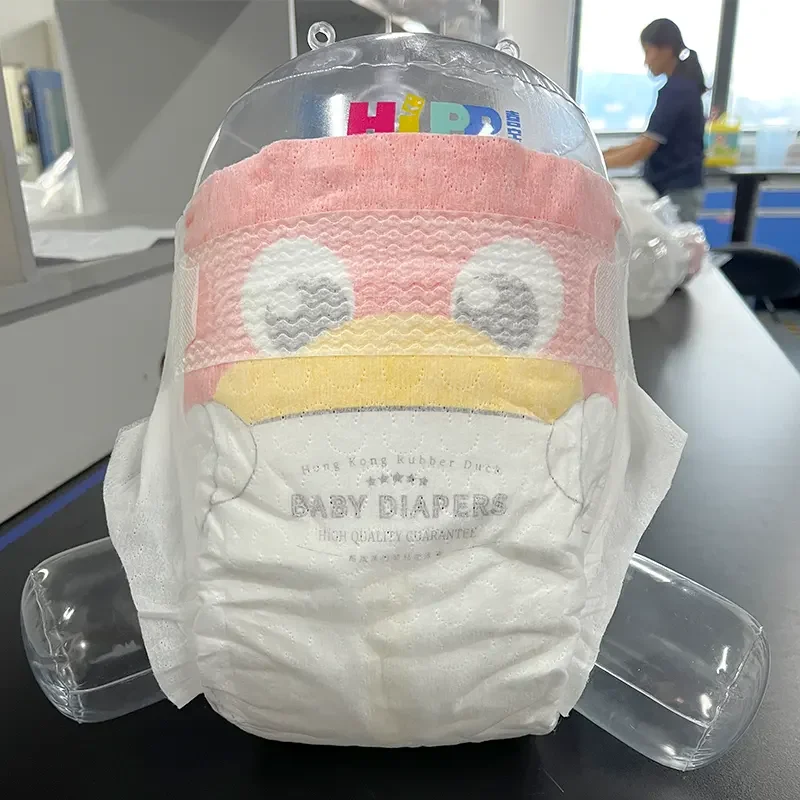

Factory Reject Baby Diapers

Untouched newborn diapers are graded down for minute visual discrepancies rather than functional issues. Perfect for aid schemes, wholesalers, and discount shops.

What Are “Factory Reject” Baby Diapers?

These are preschool factory reject diapers belonging to new and unused categories. They would not qualify for a brand’s primary sales channel because of some, non-functional issues, loss of vanity packaging, or commercial reasons. The diapers are hygienically safe, absorbent, and comfortable to wear.

Possible reasons for downgrade:

- Inventory surplus, product phase out, or canceled purchase orders.

- Off regulation weight and shape, or a balanced size ratio.

- Blemishes to packaging including mix sized ratios, and off shade colors.

- Hygienically unused and safe stock.

Never second-hand, never refurbished, never repacked from used stock. All items are hygienic and unused.

Not “Defective”—Just Stricter Standards

Hygienically factory reject products are deemed worthless if they do not pass tight packaging and visual brand checks. If these hygiene checks and core functional tests pass, discounts are then provided to the user.

What stays the same

- Hygiene-grade materials: Items manufactured on the same lines as retail products and materials are soft topsheet, fluff pulp, and stable SAP.

- Core performance within safe tolerance – absorbency, leak guard function, and overnight reliability for daily use remain unchanged.

- Skin-friendly design – breathable layers, soft leg cuffs, gentle waistbands; no reclaimed or used materials incorporated.

- Adhesives & elastic integrity – normal use recovery for stretch and tab fastening is within acceptably elastic limits.

- Basic QC for product and safety cross checks passed. Cosmetic or function deviation is non-critical and out-of-spec on outer surface.

- Clean, dry storage: Standard practices for shipment maintenance include clean and dry storage, handling the product with standard operating procedures.

What might differ

Branding and cosmetics may change logo and print alignment, color shade, embossing pattern, or print for wetness-indicator.

Spec variance may include change of minor weight and thickness, elastic tension, or tape shape and branding specification compliance.

Assortment and size mix changes include mixed Stock Keeping Units or proportions deviating from standard retail assortment averages.

Outer packaging may include unbranded or relabeled covers, non-retail cartons, or cartons that have scuffs from handling.

Simplified marks and barcodes, claims or language marks retail marketing, and marketing for retail language omitted clauses are what changes under documentation.

Batch-to-batch variation is described as visual differences of lots from various days or lines contradictions within same lot.

Who Benefits

- Discount stores and wholesale seeking fast-turnover and value Stock Keeping Units with healthy margin returns.

- E-commerce sellers constructing bundles, subscription packs, or lines that are marketed as budget lines, with priority on price rather than packaging.

- Humanitarian or non-governmental projects prioritizing budget per coverage maximization for relief program kits and community program monetization.

- Focused emerging markets and tender buyers are looking for consistent quality at the lowest payment per unit.

- Private label testers and prospective distributors are seeing if there is enough interest in the product before committing to retail pack

Is it Valued to choose factory Reject Baby diapers?

Four Key Benefits

Real Savings: Reduce landed cost per diaper without compromising hygiene or core performance.

Ready to Ship: Regular access to mixed lots and in-stock pallets for faster dispatch.

Flexible Mixes: Combine sizes and brands in one shipment to match market demand.

Easy to Sell: Clear value proposition, stable quality, and competitive margins for price-sensitive channels.

Quality & Safety Assurance

Inspection of the product line – confirm and evaluate the originating place of the product, confirm the production date, and evaluate the integrity of the lot

- Hygiene Control – Check if the sealing is in the right format, check for contaminants, and evaluate the smell of the product

- Quality Control – Check the absorbency, re-wet, elasticity of the side seams, and waist band

- Sorting and Classification – Grade by issue type and segregate based upon the forms of defects such as pack aging, overstock, cosmetics, and others.

- Multi step packing – pack in bulk and neutral coverings and pallet for bulk transport

- Final Assembly Inspection – Check the random quality of the sampled items. Take pictures and make videos as proofs of the standards of the products.

Final documentation includes COO, packing list and commercial invoice. Certificates of compliance are also available where applicable.

Product Specs & Options

- Sizes: NB / S / M / L / XL (Order for pant and pull up styles are welcomed)

- Absorbency: Available day and night; SAP/fluff absorption varied by lot

- Backsheet: PE or cloth-like film; breathable options available per lot

- Packaging: Neutral polybag. Bulk bag or mixed cartons based on lot

- Branding: Mixed/ assorted brands. Regular volumes offer private-label raw material

- Order Flexibility: Mixed size loads. Sample cartons are offered.

- Shipping: Sea or air freight; consolidated shipments accepted.

(Vary by batch consistency. We will propose the best current lots for your market.)

How We Price

- By Grade & Issue Type – cosmetic variance, packaging damage, or overstock/ overrun classifications.

- By Mix – ratio of size, assortment of brands, single-size or mixed lots preference.

- By Volume & Frequency – stronger tiers for larger or repeat orders; standing programs available.

- By Logistics Plan – EXW/FOB/CIF options and destination affects landed cost; we’ll optimize for your lane.

- By Availability – weekly published stock and spot listings unlock additional price reductions.

FAQ about Factory Reject Baby Diapers

Table of Contents

What is the Minimum Order Quantity of Factor Rejected Baby Diaper ?

Our MOQ is 40 HQ Containers, About 400,000 pcs.

Are factory reject diapers safe for babies?

Yes. They are new and unused. Downgrades are cosmetic or commercial, not hygiene or core performance. Each batch is re-inspected before shipment.

Do they come in retail packaging?

Sometimes. Many lots are shipped in neutral or bulk packaging due to carton dents or mixed lots. We’ll clarify packing type in your offer.

What quality variations should I expect?

Possible print/color shifts, outer carton scuffs, or mixed sizes/brands. Absorbency and leakage protection remain within safe tolerance for everyday use.

Can I order a custom size mix?

Yes, we can usually mix sizes and brands in one shipment depending on current stock.

What documents do you provide?

Commercial invoice, packing list, and bill of lading as standard. Certificates or test reports can be shared when available for the lot.

What about shelf life?

About 3 Years. Store in a cool, ventilated, temperature-appropriate, dry and other good storage environment.

Can I get samples?

Absolutely. We can send sample cartons or arrange pre-shipment photos/videos for confirmation.

What is your return policy?

We accept returns specifically for cases of materials mismatch based on the confirmed lot description. We document all specifications and requirements in detail in our agreements prior to shipment to mitigate any issues.

What is the difference between “Factor Rejected Baby Diaper” and “Baby Diapers”?

Only peripheral non-critical branding or cosmetic issues such as minor print misalignment or small creases on the edges of the print. The essential attributes such as absorbency, leak-proof, and breathability are maintained at Grade-A level and the production standards, as well as raw materials used, are the same.

Are “Factor Rejected Baby Diapers” hygienic and safe? Will they harm a baby’s skin?

They are absolutely hygienic and safe. All “seconds” are fully sanitized and marked through rigorous hygiene and quality control, meet relevant national standards, and the topsheet is non-irritating and soft, so it will not harm a baby’s skin. They are produced in the same materials and in the same workshop and lot as the premium products, and only do not meet the rigid standards of our premium clients in terms of appearance and may have minor, non-functional cosmetic flaws. “Factor Rejected Baby Diapers” are as safe and effective as the graded products.

Request Quote Now !

Our professional experts are ready to partner with you in developing your business.