Who we are: An OEM/ODM factory focused on baby diapers. For you, stable absorbency means fewer after-sales issues, more repeat purchases, and stronger word of mouth. This article explains—through materials, structure, process, and lab testing—how we achieve reliable absorbency, and it includes a practical workflow and validation checklist from sampling to mass production to help you evaluate and benchmark your current supply chain.

Why Absorbency Drives Repeat Purchase & Word of Mouth

Absorbency protects babies’ health and comfort. When parents evaluate diapers, the first ask is simple: “Don’t harm the baby.” If absorbent materials retain fluid poorly, the skin stays wet for longer, increasing the risk of irritation. Slow or insufficient uptake can leave a film of moisture on the topsheet, keeping the skin in contact with urine—an unpleasant condition that can escalate to diaper rash (napkin dermatitis).

“Dry feel” matters. Super-absorbent polymers (SAP) and distribution layers are strategically placed so the topsheet quickly pulls in moisture while the core rapidly locks it away. Parents notice: “the baby’s bum is dry.” Dryness supports comfort and confidence, which in turn supports repurchase.

Parents also value care efficiency. Reliable absorbency reduces night-time wake-ups, emergency outfit changes, and laundry—conveniences that translate directly into repeat purchases and positive reviews.

Absorbency determines parents’ “care efficiency and peace of mind,” influencing repurchase

| Scenario | Experience with strong absorbency | Experience with weak absorbency | Impact on repeat purchase / WOM |

|---|---|---|---|

| Nighttime use | High single-use capacity supports ~6–8 hours (aligned with sleep cycles) with no middle-of-the-night changes; baby sleeps through; parents rest. | Leaks in 1–2 hours; frequent wake-ups; crying; soiled bedding and extra cleaning. | “Leak-free nights” are core purchase drivers. Frequent leaks lead to total abandonment and concentrated complaints. |

| Daytime activity | Fast uptake prevents side leaks during rolling/crawling; fewer checks and changes; uninterrupted play. | Slow uptake causes bulging/sagging and side/back leaks; spare outfits required; outings become troublesome. | Parents repurchase products that “don’t interrupt play” and “don’t need frequent changes.” |

| Outings / long trips | Reduced change frequency lowers exposure to inconvenient public changing; “outfit saver.” | Unscheduled leaks force emergency changes and backups. | High-absorbency products gain proactive advocates; leaky products get “do not buy” reviews. |

Positive WOM keywords: “no leaks,” “actually dry,” “sleeps through,” “fewer rashes,” “soft & thin.” Negative WOM often concentrates on: “rash after two uses,” “multiple soaked pants in one night,” “can’t lock in urine.” Absorbency sits at the heart of “health & safety,” so failures are hard to redeem.

Laboratory System & Core Technologies

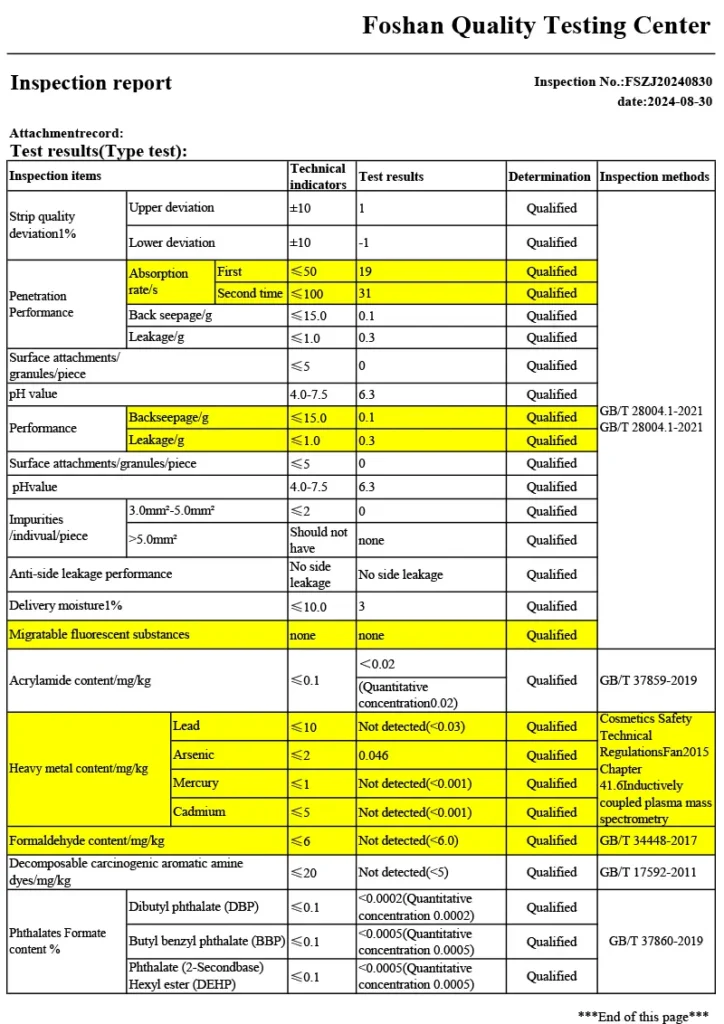

We start with scenario-based lab testing that simulates real-world use (overnight, active daytime, and long outings). We target performance against dual standards—China GB/T 28004-2021 and EU EN 13726—plus internal requirements built around parent pain points.

1) Uptake speed (fast surface clearance)

- Urination profiles: 100 mL fast discharge (night) and 5 × 20 mL small discharges (day).

- Method: High-speed video (240 fps) measures time to surface disappearance across three critical zones (front waist, back waist, sides) to prevent slow local uptake when the baby turns.

2) Rewet / backflow (dry under pressure)

- Pressure block: 5 kg (≈ the load from a 10 kg infant).

- Premium target: rewet < 1 g under press; 8-hour extended test with periodic presses targets < 2 g.

3) In-use absorbency & leak dynamics

- Size L in-use absorbency target: ≥ 600 mL.

- Motion rig: 200 mL dosing with programmable sequence: 10 min supine → 5 min side → 10 min crawling → 5 min walking; premium criterion aims for ≤ 2 mL backflow/rewet per press during the cycle.

- Segment leakage tests: focus on leg cuffs and back-waist pocket.

4) Absorption uniformity (no clumping, no bulging)

- Cryo-section & microscopy: after 200 mL dosing, confirm even SAP distribution; post-swelling particle size variance ≤ 20%.

- Core thickness variation: < 1.5 mm across zones to avoid friction, shifting, and localized leaks.

5) Protective structures (targeted leak-guards)

- Leg cuffs: 3.5 cm height, dual-layer spandex for a soft seal at rest and dynamic stretch during motion.

- Back-waist pocket: 3 cm depth with inner absorbent nonwoven; designed to catch stray liquid (≥ 20 mL) during supine sleep.

Materials that enable performance

- Core design: Uniformly distributed high-polymer SAP + composite distribution layers; hot-melt lamination to prevent SAP agglomeration/voids; thin-filled, fast-spreading core with strong lock-in.

- Topsheet: Hot-air nonwoven with hydrophilic finish controlled at ~5 g/m² to prevent pooling and promote rapid, even flow into the core.

From Data to Machine: Converting Lab Wins into Scale

We engineer our lines to replicate lab outcomes consistently:

- Unlocked cores: Light, thin cores with uniform SAP distribution maintain high capacity without clumping.

- Leak-guard geometry: Cuffs and back-waist pocket tuned for seal and catch performance without pinching.

- Process windows: Dryer temperature, fiber matrix formation, and hot-melt application are controlled to lock in capillary pathways for fast uptake and deep lock-in.

Quality Assurance: End-to-End Data Control

Incoming materials (every batch)

- Bench tests: rewet and absorbency screens; any out-of-spec batch is rejected.

- Formula discipline: Nonwoven/finishes kept within tight tolerances to prevent product drift.

In-process control (real-time)

- Core thickness gauge: 10 points/meter; delta > 1.5 mm triggers auto-alarm & laydown adjustment.

- Leak-tightness tester: Randomly sample ~1%; 50 mL dosing under motion; any leaks → reject.

- Weight checker: if single-piece weight deviates by > 2 g, auto-sort to keep basis weight/absorbency stable.

Pre-shipment sampling (every lot)

- 50 pcs selection: distributed across line positions; test uptake, rewet, and max absorbency—all must pass.

- Dynamic leak test: additional 10 pcs under motion; if total leakage > 5 mL for the lot, rework before release.

Lot-to-lot consistency: maintained via raw-material inspection, in-process monitoring, and final testing with traceable records. N-consecutive-lot data can be shared under NDA.

Buyer Workflow & Supplier Validation Checklist

Recommended evaluation workflow

- Define scenarios & specs: overnight hours, daytime activity profile, outing duration; set rewet/uptake targets and size-specific capacity needs.

- Request lab sample kit: include material sheets, core cross-sections, and machine settings ranges used to produce the samples.

- Scenario tests (your side): run 100 mL fast and 5 × 20 mL dosing; check surface clearance in 3 zones; run press/rewet and motion leak tests.

- Wear trials: collect parent feedback on dryness, leakage, fit, and change frequency across day/night.

- Pilot lot: confirm in-process QA data (thickness map, weight control, leak-tightness sampling) matches lab runs.

- Golden sample lock-in: sign off materials (SAP grade, nonwoven spec, hydrophilic finish), process windows, and acceptance criteria.

- Mass production monitoring: require COA per lot (uptake/rewet/leak), retain samples, and monthly SPC summary.

Supplier validation checklist

- Dual-standard testing capability (e.g., GB/T 28004-2021, EN 13726) with documented methods.

- Scenario-based lab (high-speed video, programmable motion rig, press/rewet apparatus).

- Clear targets for rewet (<1 g press; <2 g extended), size-specific in-use capacity (e.g., L ≥ 600 mL).

- Core uniformity controls (thickness delta <1.5 mm; SAP distribution checks via microscopy).

- Protective structures validated (leg cuff height/spec; back-waist pocket capacity ≥20 mL).

- Incoming QC with batch-wise bench tests; reject criteria defined.

- In-line leak-tightness sampling (~1%), auto-sort by weight deviation (>2 g).

- Pre-shipment lot testing plan (≥50 pcs; dynamic leak testing; rework rules >5 mL).

- Traceable records & N-consecutive-lot data available under NDA.

- ODM flexibility (appearance, prints, tabs, packaging, barcodes) with artwork workflow.

FAQ

How is supply chain & delivery capability impacted?

Consistency is maintained through end-to-end quality control—raw materials inspection, in-process monitoring, and final testing. Each step has guardrails and records.

Do you support OEM/ODM and changes to appearance, printing, waist tabs, packaging, and barcodes?

Yes. Share your artwork and requirements; we will tailor appearance, prints, tabs, packaging, and barcodes to your needs.

Where can I get product samples for evaluation?

We provide existing products for testing and comparison. Samples are free; you only bear international delivery costs. For larger quantities or custom requirements, a sampling fee may apply.

Can you replicate a competitor’s product?

Not guaranteed—it depends on the sample. We can deliver equal or greater quality and propose unique selling features to support market penetration.

Contact & Next Steps

- Request a sample kit (lab-made + pilot lot) with data sheets and test reports.

- Share your ODM brief (target sizes, scenarios, branding, packaging/barcodes).

- Ask for N-consecutive-lot QA data under NDA.

Let’s engineer leak-free nights and drier days—reliably, at scale.

Contact Us